Forensic Fuel Tank Inspection & Petrochemical Consultants, Sydney Australia

Future Proof Your Service Station With Our 30 Year Tank Lining Warranty

John G. Pohl, Director

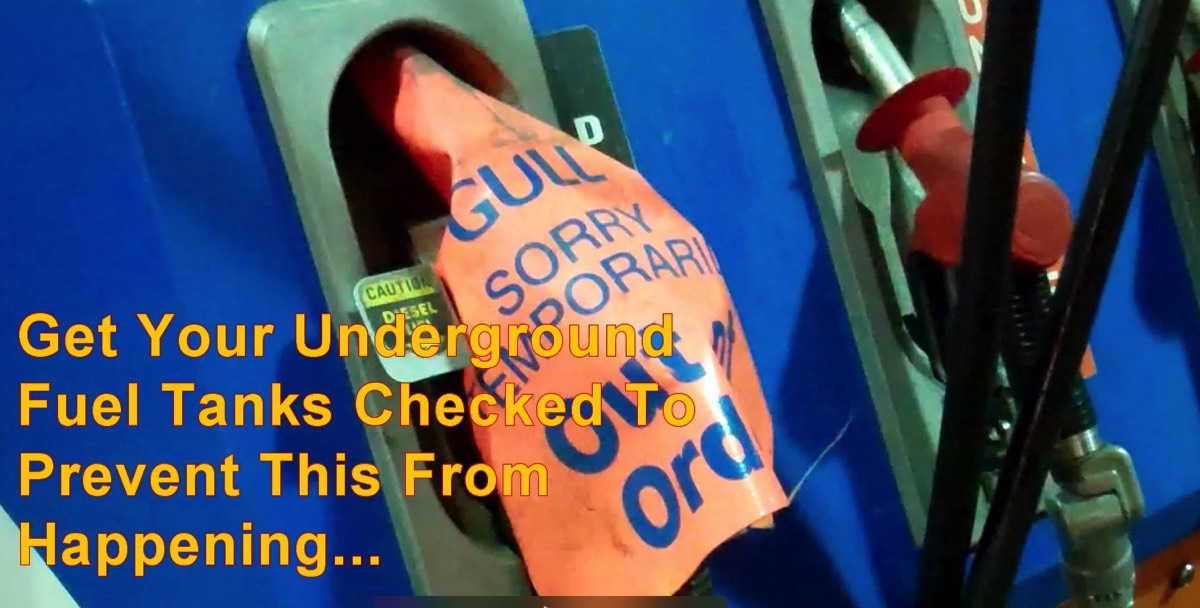

Water in fuel can be costly and bad for your service station reputation. In addition, you will be required to carry out a costly and time consuming Loss Detection Investigation as specified by the EPA….

JG Pohl, Director, Integral Environmental Solutions Pty Ltd

Sydney Australia

EPA recommends UPSS owners check for corrosion in their tank systems storing diesel fuel; this applies to

both steel tanks and systems with fibreglass tanks. Owners reporting corrosion sometimes find sludge or particles, which may like coffee grounds, clogging their fuel filters. EPA recommends all owners of UPSS systems storing diesel fuel conduct a visual inspection by checking in their filters and inside UPSS system access points even if they have not seen symptoms in the filter; severe corrosion may already be established before symptoms appear in the fuel filter and an owner becomes aware of a severe corrosion issue.

Remember that this initial diagnostic observation of UPSS equipment visible from the surface may not show if corrosion or damage even if it exists in the UPSS system.

Water in fuel can be costly and bad for your service station reputation. In addition, you will be required to carry out a costly and time consuming Loss Detection Investigation as specified by the EPA reporting guidelines.

Even if your tank is not taking on water, but has been in the ground for several decades, it is still recommended that at minimum, you have a man-hole installed and get us to clean-out and conduct a forensic “eye’s on” internal inspection to check the tank integrity before a problem occurs.

Our Forensic “Eye’s On” Internal Fuel Tank Inspection & Reporting Process

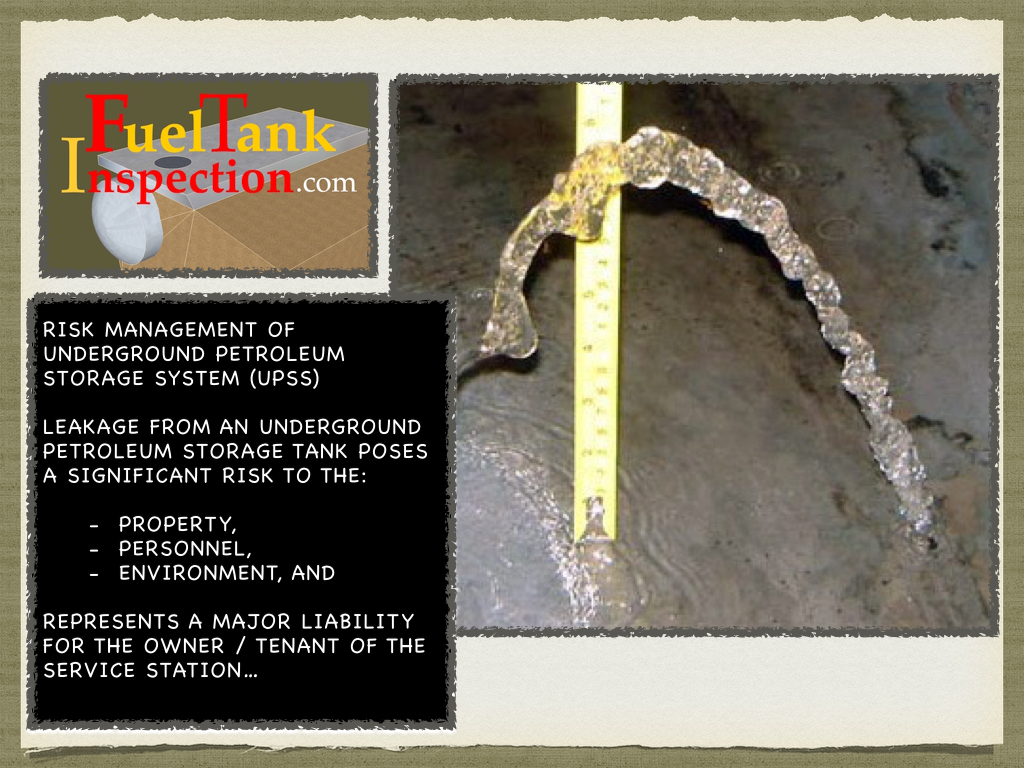

Risk management and your underground fuel tank, or Underground Petroleum Storage System (UPSS) system.

JG Pohl, Director

Risk management and your underground fuel tank, or Underground Petroleum Storage System (UPSS) system.

JG Pohl, Director

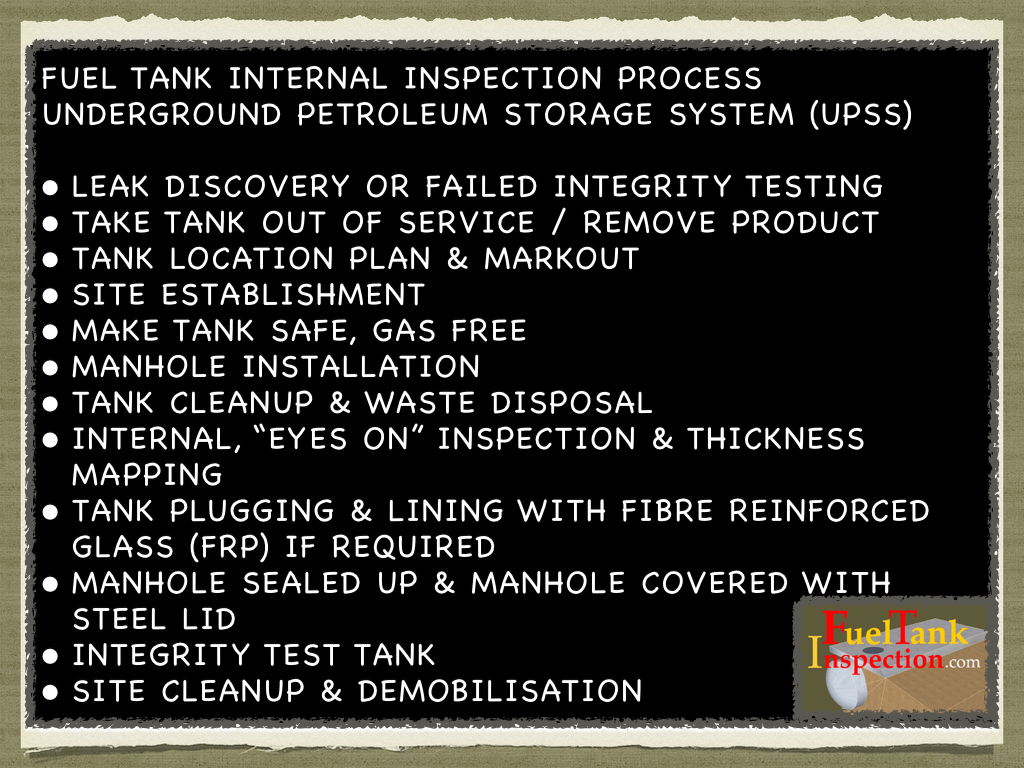

Internal fuel tank inspection process.

JG Pohl, Director

When your fuel tank is out of service due to water ingress, your loosing lots of sales and ruining your reputation.

JG Pohl, Director

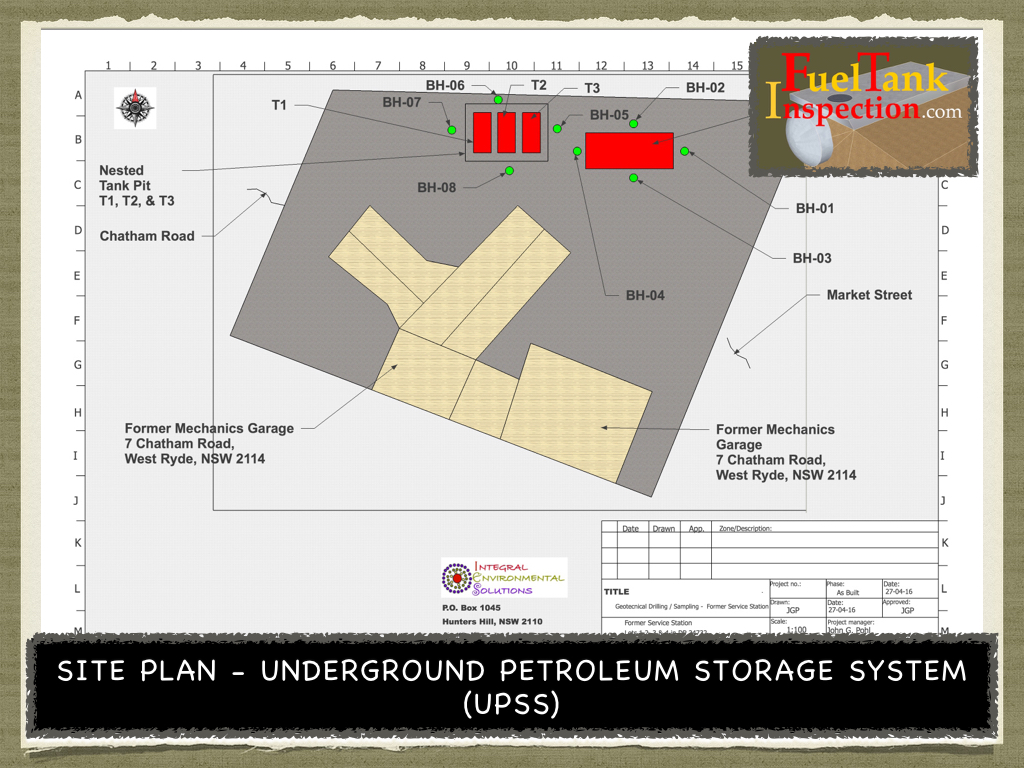

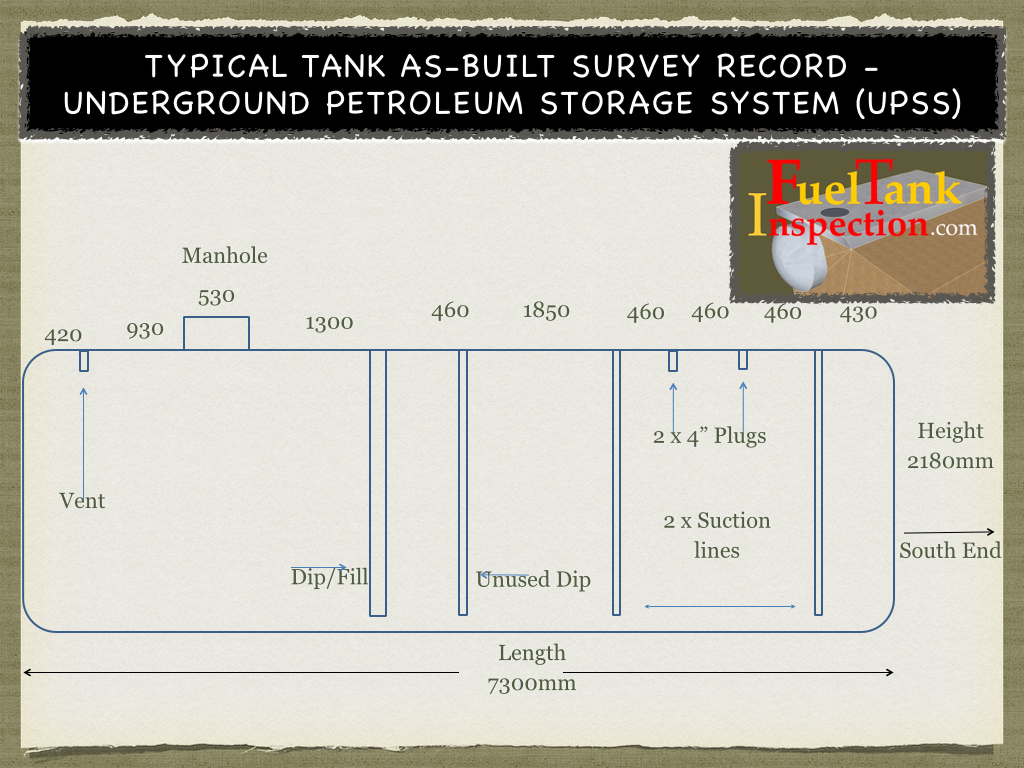

Before we perform any internal fuel tank inspections, we survey the site and develop an engineering drawing on tank sizes, location and orientation.

JG Pohl, Director

Fuel tank site mark out is a critical step before in-situ placement of permanent manholes.

JG Pohl, Director

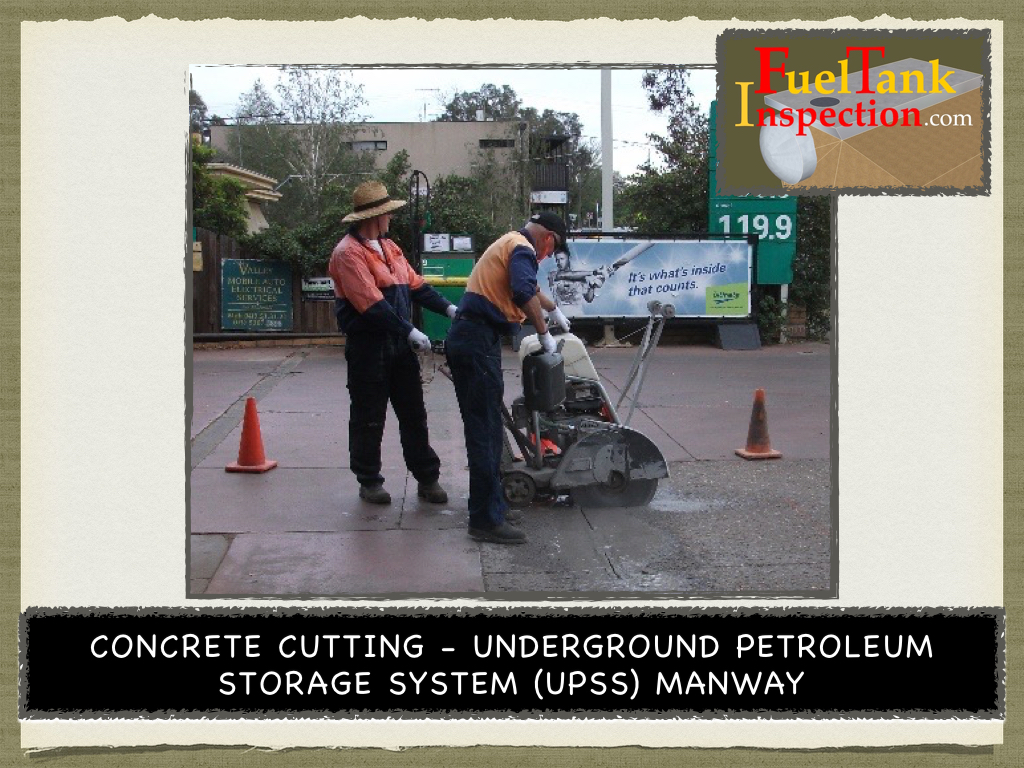

We typically cut a one square metre access opening in forecourt for installation and placement of permanent manhole.

JG Pohl, Director

Permanent manhole installed to gain access to tank internals.

JG Pohl, Director

Confined space hoist system utilised for men working down inside tank.

JG Pohl, Director

Liquid waste disposal company commissioned to remove liquid and sludge wastes inside tank prior to internal inspection.

JG Pohl, Director

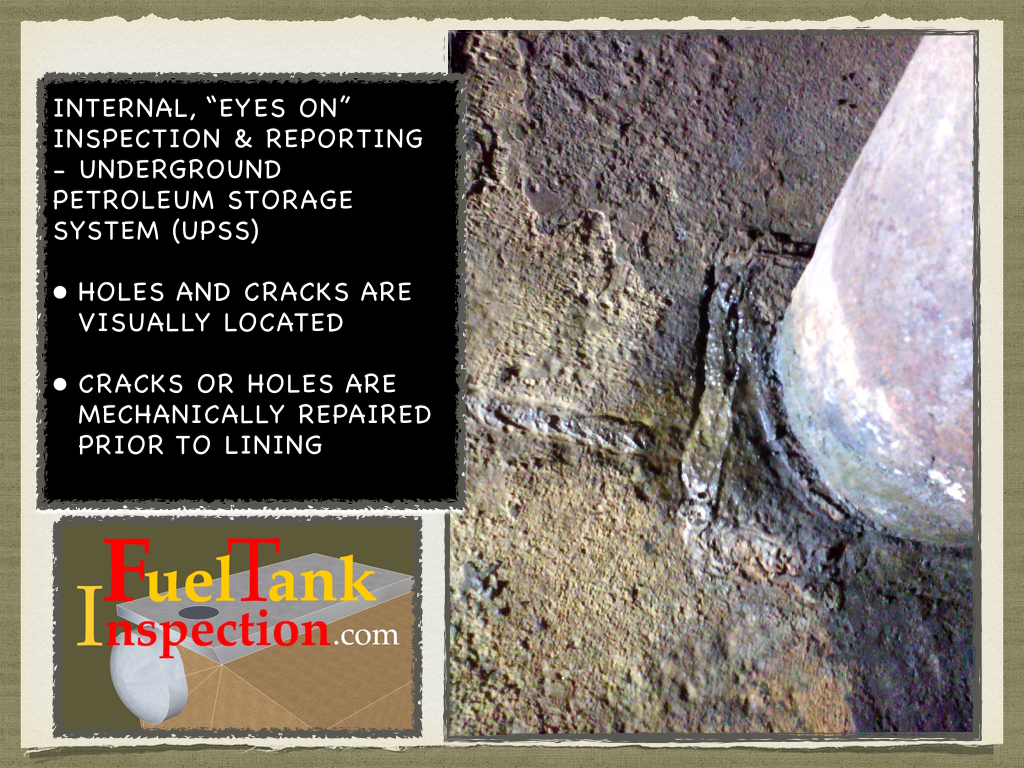

Once a tank is de-sludged and cleaned, we proceed with internal tank inspection.

JG Pohl, Director

A cleaned tank reveals defective tank wall & likely entry point for groundwater or release of fuel to environment.

JG Pohl, Director

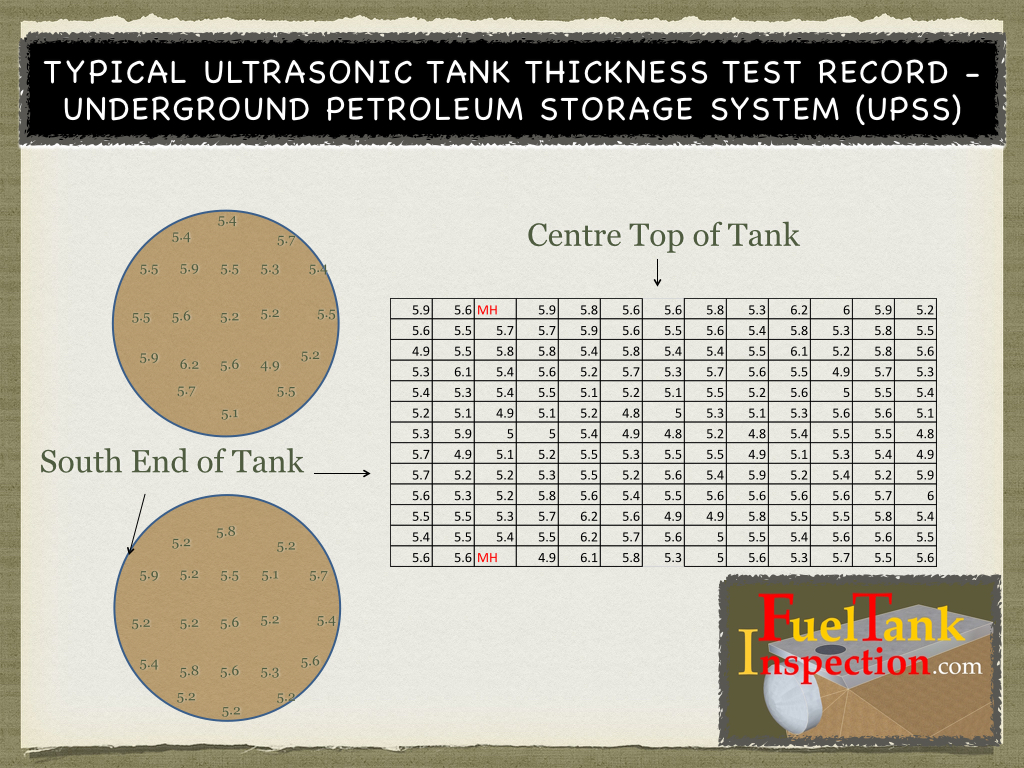

Internal tank wall thickness testing is carried out and a test record is generated as part of our reporting process. If we measure tank wall thickness is within engineering guidelines, we can repair and re-line a tank.

JG Pohl, Director

Internal tank wall thickness test survey for the service station managers records.

JG Pohl, Director

As-built of internal tank fittings and pipe-works for the service station managers records.

JG Pohl, Director

In many cases, if we find excessive internal corrosion and holes inside the Underground Petroleum Storage System (UPSS), we have the service of full internal plugging and lining with Fibre Reinforced Plastic (FRP) giving you peace of mind for an additional 25 years of service life.

JG Pohl, Director

Unobtrusive, tidy & clean manhole installed in forecourt.

JG Pohl, Director